2022-01-20 09:48:46 Writer:

On January 13, 2022, EA die casting, L.K. group, Ningbo sciveda, Longda aluminum successfully held" integrated body structure die-casting technology BBS "and" integrated body structure project strategic cooperation signing ceremony ".

01 Participants

EA chairman of Mr Zhang dehui, Longda aluminium President Mr Du Yongli, tsinghua university doctoral tutor/advanced molding manufacture key laboratory of the Ministry of Education, deputy director of Xiong Shoumei, EA vice President Mr Bai Yanpeng, EA die casting, general manager of Mr Lu Deyu, GWM technology center, deputy general manager ms HuoCongMin etc attended the on-site activities. Mr Liu Zhuoming, CEO of L.K Group, Mr Zhang Jun, General Manager of Ningbo L.K. and Mr Ren Sailiang, Chairman of Ningbo sciveda attended the event online.

EA die casting General Manager Lu Deyu delivered a speech

03 Integrated body structure die casting technology Forum

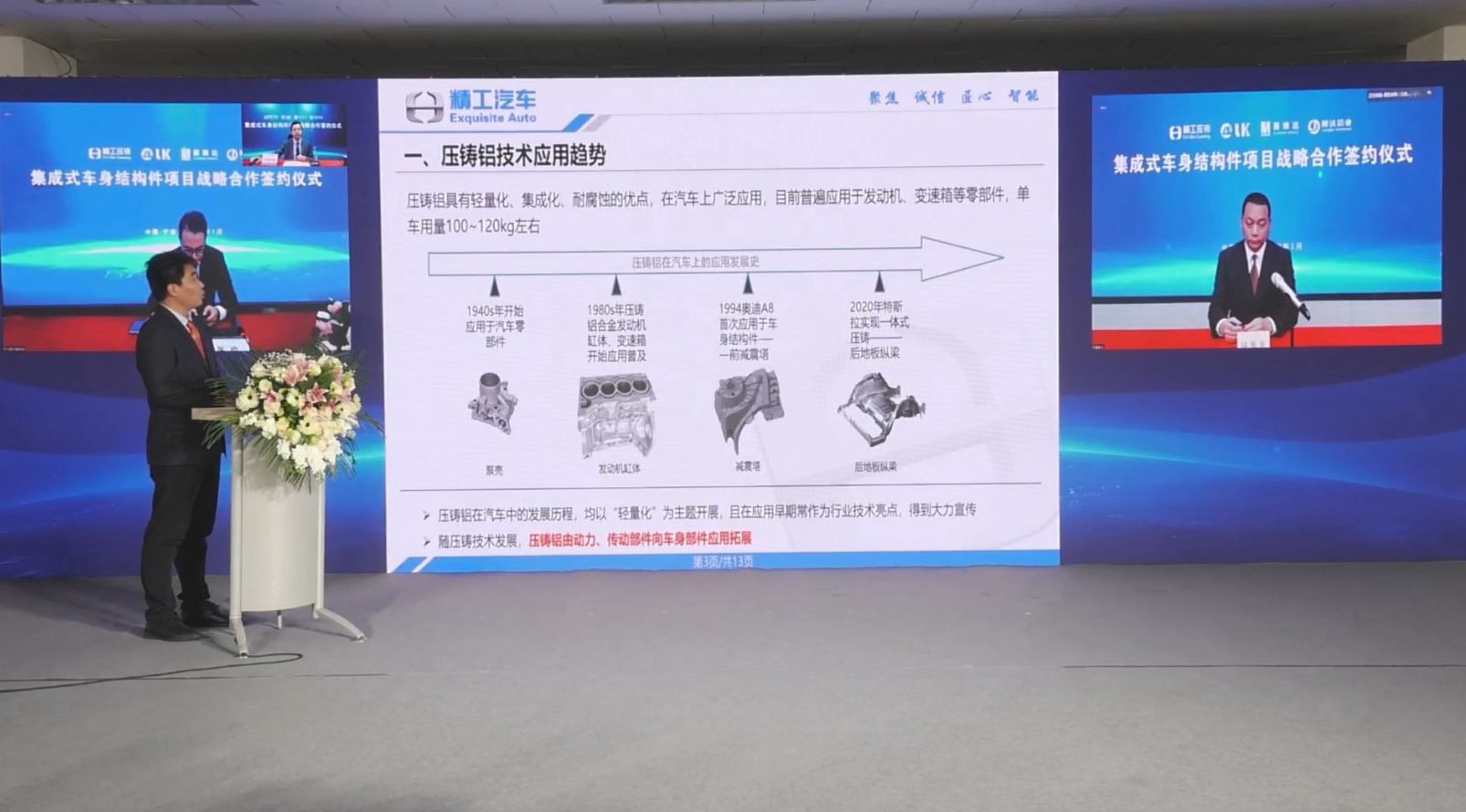

"Integrated body structure die-casting technology BBS" invitation from GWM, tsinghua university, L.K.group, ningbo sciveda, Longda aluminium, suppeium, automobile structure lightweight design, high vacuum die casting, smart and avoid heat treated alloy die-casting unit, simulation technology etc., published a keynote speech.

He Zhijie, senior body engineer of GWM, delivered a keynote speech on "Lightweight Design of Die cast Aluminum Body"

Prof. Xiong shoumei shared the latest research results of high vacuum die casting technology and die casting aluminum alloy materials

Li Jianjun, technical director of Ningbo L, shared the scene application of L.K.Group super-large intelligent die casting unit in the manufacturing field of large automotive structural parts

Deng Yanchao, deputy general manager of Ningbo Sciveda, shared the design experience and previous successful cases of temperature control system and pouring and drainage system of die-casting molds for large structural parts

Guo Junhui, Executive Vice President of Longda Aluminum, shared the research progress of heat-free alloy for die casting structural parts and Longda heat-free new materials

Xue Pengji, director of suppeium, delivered a keynote speech. Simulation analysis will provide strong technical support in the field of intelligent development and intelligent manufacturing of die casting

During the forum, the organizers specially organized expert interviews. Professor Xiong Shoumei of Tsinghua University, Huo Congmin, Deputy general manager of GWM Technology Center, Lu Deyu, General manager of EA die casting, Guo Junhui, Executive Vice President of Longda Aluminum, Zhang Jun, General manager of Ningbo L.K.group and Ren Sailiang, Chairman of Ningbo Sciveda participated in the exchange.

They discussed and exchanged views on the development trend of the industry, the research and development of aluminum alloy materials and the lightweight manufacturing of car body. Experts agree that the current automotive industry is undergoing great changes unseen in a century. Lightweight manufacturing of new energy vehicles and integrated die casting of automotive structural parts are becoming development trends.

Lu Deyu, general manager of EA die casting, said that EA die casting has many years of practical experience in key production technologies of structural parts, such as high vacuum process, mold temperature control technology and so on, and now has the technical foundation to produce large body structural parts. Next, will accelerate the implementation of transformation, construction of structural parts production base, to build the industry benchmark!

04 Signing ceremony of integrated body structure parts Project

After the forum, the "Signing ceremony of integrated body structure parts Project" was entered. Mr. Li Hua, director of Precision die casting project, first introduced the progress of integrated body structure parts project. The application study shows that the integrated die casting technology has advantages in weight reduction, production process simplification, labor reduction and other aspects, and has broad application prospects. The weight reduction efficiency of the product after the application of integrated die casting reaches 24.6%. Compared with the steel-aluminum hybrid form, the dissimilar connection is eliminated, the manufacturing process of underbody is simplified, and the automation rate and production efficiency are improved. Direct labor fell by 62 percent.

Currently, EA die casting has completed product design, vehicle performance simulation analysis, mold design and verification, and the project is about to be implemented. Through the strategic cooperation with leading enterprises of equipment, mould and material in the industry, the smooth implementation of the project is guaranteed.

Mr. Liu Zhuoming, CEO of L.K. Group, Mr. Ren Sailiang, chairman of Ningbo Sciveda, and Mr. Du Yongli, President of Londa Aluminum delivered speeches respectively. All responsible suppliers indicated that they would provide more high-quality and efficient technical support and services for Precision die casting through this strategic contract, so as to ensure the smooth operation and production of the project!

Mr. Zhang Dehui, chairman of EA, made a concluding speech. He said that the "new four modernizations" -- electrification, intelligence, Internet connection and lightweight -- are profoundly changing the product form and technical framework, manufacturing process and the entire industrial chain and value chain of traditional cars, and will become the development direction of future cars. The strategic cooperation between EA die casting and L.K. group and other enterprises will certainly promote the development of integrated aluminum alloy body parts in China. Give full play to each other's expertise and advantages in their respective fields, sincere cooperation, mutual benefit and win-win, to achieve efficient coordination of projects, and make our cooperation into a benchmark and model in the aluminum alloy casting industry.

EA die-casting and L.K. Group, Ningbo Sciveda and Longda Aluminum signed strategic cooperation agreements on integrated body structure parts project respectively.

With the release and implementation of the strategy of die casting integrated body structure parts, relying on the strong support of equipment, mold and material partners, the combined force of the strong will surely promote The company to strive hard on the track of automotive lightweight, catch up and compete for the lead, and accelerate the transformation to the world's leading professional manufacturer of aluminum alloy structure parts!